Products in stock

Unlike many other portable beer cooling boxes, this model is equipped with a quality cooling box. This is a rotomolded cooling box with high-density PU insulation that can keep ice in the cooler for several days. With a built-in bottle opener, drink holders, and a fisherman-friendly ruler, it's the best available on the market.

The unit's cooling plate is made from new high thermal conductivity aluminum, while taps, shanks, and other parts are made of stainless steel.

Often, other portable cooling systems are made with stainless steel coils. These are cheaper to produce, but cast aluminum cooling plates have high thermal mass, acting like a large heat sink and helping transfer heat more efficiently. Another advantage of cast aluminum cooling plates is that they are compact and allow more free space in the cooler, so you can place other drinks above the cooling plate.

If you're looking for a commercial-grade portable cooling box that will last a lifetime, this is what you need.

This kit includes: 1 x 35L Jeti Fundra cooler, 2 x Nukatap FC Gen2 taps, 2 x stainless steel long shank with Duotight fittings, 2 x black plastic tap handles (long slender type), 4 x Duotight 8mm elbow fittings, 1 x 5mm x 8mm EVABarrier beer line, 4 x Duotight 8mm x FFL fittings

The cooling box has all holes pre-drilled for your convenience. You just need to push the hoses together, tighten a few nuts, and you're ready to pour drinks.

NOTE: Kegs and connectors must be purchased separately.

INSTRUCTIONS: 1. Connect the kegs to the beer inlet lines of the cooler. Fill the cooling plate with beer. It's important to fill the cooling plate tubes with beer FIRST. If there's water in the tubes and you then put very cold ice on the cooling plate, the water in the tubes might freeze, blocking fluid flow. So ensure there's beer in the tubes, as full-strength beer freezes at 4°C lower than water. 2. Fill the cooler with ice. For best results, THE ICE MUST BE IN CONTACT with the aluminum cooling plate. To ensure ice contact with the cast aluminum, leave the cooler drain open so water can drain out. If you leave water in the cooler, the ice will eventually float and lose contact with the cooling plate. 3. Set the regulator to about 30 psi. This high pressure is necessary to push the beer through the cooling plate, which has significant tube resistance.

NOTE: If your kegs are cold and you're using CO2 for dispensing, remember that extended periods at elevated pressure can over-carbonate the beer. If your kegs are at room temperature, this shouldn't be an issue as CO2 doesn't readily dissolve in warm beer. However, if you do have cold kegs and are dispensing at elevated pressure, you might consider using either pure nitrogen or a CO2/nitrogen mix for dispensing. Alternatively, if you're only dispensing at elevated pressure for a few hours, this usually isn't long enough for the beer to over-carbonate.

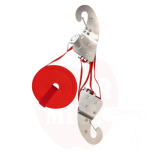

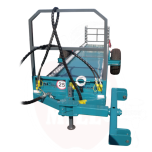

The hydraulic fork lift for tractor is designed for loading and unloading goods placed on pallets, in containers and boxes, and for transporting them over short distances. The loader is a device mounted on the three-point linkage system (TUZ), designed for 0.6-0.9T class tractors with external hydraulic output (single-acting cylinder). Maximum lifting height is 2.4 m and the maximum lifting capacity is 700 kg.

The hydraulic fork lift consists of two main components: the lifting mechanism and loader frame, and the cross bar of the tractor's three-point linkage system. The lifting mechanism consists of outer guide, inner guide, fork plate, lifting forks, piston cylinder, and lifting cable. The frame consists of steel frame construction, supports (left and right), and double-acting piston cylinder. Components required for hydraulic system installation are supplied separately.

The product is delivered directly from manufacturer's warehouse and transport cost is calculated in the shopping cart.

The device is easy to use - it attaches to the tractor's three-point linkage system and connects to the tractor's hydraulic system. The loader enables lifting and transporting heavy cargo boxes or pallets, moving them to the required location. The lateral hydraulic shift device allows the forks to move sideways, enabling more precise positioning when handling cargo.

Technical parameters: Model: PHW-240/T Machine type: Mounted on tractor TUZ Weight: 310 kg Lifting capacity: 700 kg Lifting height: 240 cm Fork spacing: 26-90 cm (adjustable)

Overall dimensions: Length: 45 cm Width: 96 cm Height: 176 cm

.png)