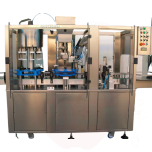

MONOBLOCK 6-1 ISO 850pdl/h

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 2000000036298

Unit: pc

Stock qty: On special order

Delivery time: Eritellimustoode / Please contact / Ota yhteyttä

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 22% VAT.

Automatic Isobaric Filling Machine for Carbonated Beverages

The fully automatic isobaric filling and capping machine is designed for filling carbonated beverages with pressure up to 5 bar. The machine's productivity ranges from 600-850 bottles per hour, depending on the beverage type and bottle format.

Technical Specifications

- Power supply: 400V, power 3kW

- Compressed air consumption: 120l/min at 7 bar

- Connections: Tri-clamp standard

Bottle Parameters

- Minimum diameter: 55mm

- Minimum height: 110mm

- Maximum diameter: 110mm

- Maximum height: 350mm

Capping System

The machine is equipped with an automatic crown cap vibrating hopper and feeding system. Compatible with 26mm or 29mm crown caps. The entire work process is conveniently controlled through a central control panel.

Keywords: filling machine, carbonated beverages, isobaric filler, bottle filling, crown caps, bottle filler, automatic filler, beverage filling machine

| Weight (kg) | 0.000000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

.png)