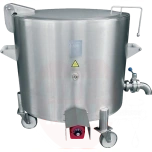

Kettle 300L 22kW gas thermostat+ mixer

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 2000000009001

Unit: pc

Stock qty: Pre-order

Delivery time (day): Eritellimustoode / Please contact / Ota yhteyttä

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Industrial Gas-Heated Stainless Steel Kettle 22kW

Powerful and durable 22kW gas-heated industrial kettle ideal for production processes. The kettle ensures efficient 2.2m³/h capacity.

Main features:

- Enclosed burner in oil jacket ensures even heat distribution

- Robust stainless steel construction for long service life

- Round tank with practical rectangular housing

- Bottom-mounted scraper agitator for uniform processing

- High-quality thermal insulation for energy savings

Precise control:

- Accurate thermostat-microprocessor controller

- Adjustable agitator rotation speed

- Convenient discharge valve for easier maintenance

- Round tank edges ensure better cleanability

This professional gas-heated kettle is designed to ensure maximum productivity and reliability for industrial processes.

| Weight (kg) | 420.000000 |

| High (m) | 1.31 |

| Width (m) | 1.1 |

| Length (m) | 1.72 |

.png)