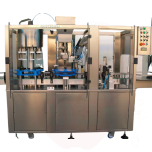

Isobaric filler RLV2-iSo

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 2000000029634

Unit: tk

Stock qty: On special order

Delivery time: Eritellimustoode / Please contact / Ota yhteyttä

Leveranstid inom Estland för lagervaror ca 3-5 arbetsdagar. OBS! På grund av den snabba prisökningen kan priser för icke-lagervaror ändras utan föregående meddelande! Standardpriser med 22% moms.

Video

Professional Isobaric Filling Machine with 6 Nozzles

High-quality Italian isobaric filling machine specifically designed for carbonated beverage filling. The machine is equipped with 6 foam-reducing nozzles, ensuring an efficient and precise filling process.

Technical Specifications

- Maximum filling pressure: 5 bar

- Power consumption: 0.37 kW (220V)

- Compressed air consumption: 120 l/min (6 bar)

- Control voltage: 24V

Dimensions and Capacity

- Height: 1.92 m

- Width: 0.8 m

- Depth: 0.40 m

- Maximum bottle height: 350 mm

- Maximum bottle diameter: 120 mm

Applications

Ideal solution for filling:

- Beer

- Cider

- Sparkling wine

- Carbonated water

Available Accessories

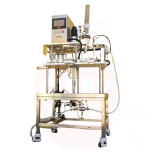

- Automatic filling system

- Pneumatic pump system

- Container cleaning system (water and air or air only)

- Capping machine

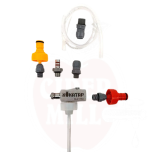

- 1" connection valve seal kit

- Adjustable filling level tubes

- Bottle models for valve maintenance

- Non-return valve

Keywords: filling machine, isobaric filler, beer filler, cider filler, carbonated beverage filler, capping machine, bottle filler, beverage industry equipment

.png)