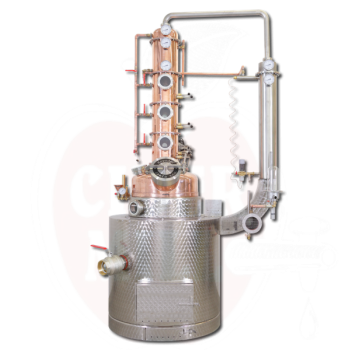

Distilors for 200l for brandy

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 2000000013190

Unit: tk

Stock qty: On special order

Delivery time: Eritellimustoode / Please contact / Ota yhteyttä

Leveranstid inom Estland för lagervaror ca 3-5 arbetsdagar. OBS! På grund av den snabba prisökningen kan priser för icke-lagervaror ändras utan föregående meddelande! Standardpriser med 22% moms.

Professional Distillers 100-200 Liters

We offer quality distillation equipment with capacities of 100L, 150L, 170L, and 200L. The fully automatic system eliminates the need for secondary distillation.

Technical Features

- Single, double, or triple-stage distillation blocks

- Deflectors with catalyst installation capability

- Built-in washing system

- DN 100 sight glasses with lighting

- Stainless steel construction

- 4-inch discharge valve

Heating Systems

- Gas burner (natural gas/propane-butane): 40-75 kW/h

- Electric heating: 21-40 kW/h

- Solid fuel (wood)

- Combined heating system available

Technical Dimensions

- Height: 3100 mm (3300 mm with catalyst)

- Installation space: 2000 x 2800 mm

- Block width: 2800 mm

- Filling port diameter: 250 mm

Performance and Benefits

- 50% faster distillation process

- 30% higher production volume

- Low water consumption for cooling

- Easy to use

- Higher distillate quality and purity

- More intense aroma profile

- Energy-efficient operation mode

Available Accessories

- Automatic cooling control thermostat

- Gas burners for different fuel types

- Digital thermostat for electric heating

- Copper wire or ceramic bead catalyst

- Integrated lighting system

- Steam mixing system

- Motorized mixture mixer

- Heat exchanger

Keywords: distiller, distillation equipment, alcohol distillation, industrial distiller, professional distiller, stainless steel distiller, large-scale distiller, distillation block

| Weight (kg) | 0.000000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

589,00 €

.png)