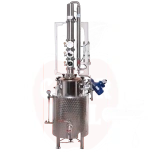

Distiller 50L AABRATEK OVM/LM with sight glass

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 20000000541675

Unit: pc

Stock qty: Pre-order

![]()

![]() Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

Delivery time within Estonia for stock items approx. 3-5 working days. NOTE! Due to the rapid price increase, prices for non-stock items may change without prior notice! Standard prices with 24% VAT.

AABRATEK OVM/LM DISTILLER WITH SIGHT GLASS

Specification:

KEG container with a capacity of 50 or 30 liters (optional) with electric heating elements: 2+2kW for the 50L container and 2+1.5kW for the 30L container, including cover and wiring. The set includes a drain valve and bimetallic thermometer. Containers are insulated with Armaflex rubber foam. The set includes two electronic panel thermometers that measure temperature with an accuracy of 0.1°C and a refresh rate of 1s.

SMS connections.

Stainless steel corrugated radiator 3m.

Liebig condenser with a ½-inch ball valve installed 20-25cm below the top of the column filling. The total length of the condenser is approximately 70cm, with a 12mm condenser in a 25mm water jacket.

360° flashlight type sight glass.

Precision valve in the head.

Thermometers: head, 10th shelf, container (bimetallic). Thermometer probes are installed in stainless steel tube sleeves, probe with silicone seal.

Column 60.3mm x 110cm, column filling: prismatic springs made of stainless steel.

Copper catalyst, approximately 22 cm long, filled with copper in the form of prismatic springs, attached to the container with an SMS connection. The copper filling absorbs sulfur compounds, which significantly improves the taste and aroma of the distillate. The copper filling should be cleaned in a citric acid solution every 2-4 processes.

Reduced VM collection - allows us to collect larger amounts of higher quality distillate heart, with the additional advantage of a well-chilled distillate, making concentration measurements more reliable.

Drain valve.

The total height of the set is approximately 225cm.

The set is made of AISI 304/316 stainless steel.

SILICONE/EPDM seals.

Elements are welded using the TIG method under Argon protection. After welding, elements are cleaned by acid immersion.

Advantages of Aabratek distillers:

Concentration after first distillation is 95-96%, with no downward trend - we achieve the same percentage throughout the entire process.

A single distillation is sufficient to obtain a high-quality distillate; a second distillation is not necessary.

Thanks to the precision valve, reflux regulation is very simple.

Productivity of approximately 20-25ml/min.

Due to the angled radiator, the set is lower and more manageable.

Easy to use even for beginners.

Stable operation of the device without excessive electronic control.

Due to the compatibility of SMS connections, the set can be expanded at any time.

General principle of using a distiller:

A distiller is a device that allows different components to be separated based on their boiling point differences through evaporation and condensation of a liquid. When distilling alcohol, the fermented liquid is heated, the evaporated alcohol is collected through a cooling system and condensed into high-quality pure alcohol. This process removes impurities and produces a distillate with higher alcohol content.

Keywords: distiller, alcohol distillation, home brewing, distillation equipment, Aabratek distiller, OVM/LM distiller, distiller with sight glass, home distiller, high-quality distiller, stainless steel distiller, home brewing, distiller with SMS connection, reflux distiller, distillate, distiller kit, distillation apparatus with sight glass, heating device, measuring technology in beverage industry, beverage production

| Weight (kg) | 0.000000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

.png)