Blending Tank 1000L isobaric, stainless steel

![]() Professionals recommend - producers prefer!

Professionals recommend - producers prefer!

EAN: 20000000543006

Unit: tk

Stock qty: On special order

Leveranstid inom Estland för lagervaror ca 3-5 arbetsdagar. OBS! På grund av den snabba prisökningen kan priser för icke-lagervaror ändras utan föregående meddelande! Standardpriser med 22% moms.

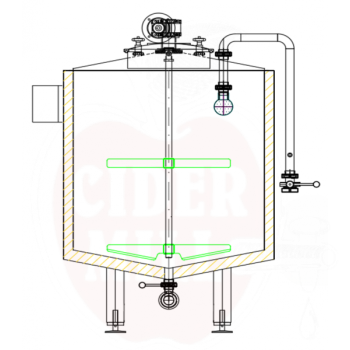

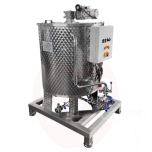

1000L Isobaric Stainless Steel Mixing Tank for Beverage Industry

Professional 1000-liter isobaric mixing tank is specifically designed for precise processing and storage of liquid mixtures under uniform pressure. The equipment is made of high-quality AISI 304 18/10 stainless steel, ensuring maximum durability and hygiene.

Technical Specifications:

- Volume: 1000 liters

- Power consumption: 0.75-1.5 kW

- 10° conical bottom and roof

- Insulated cylindrical section and bottom

- Thermal exchange system

Main Components:

- 400 mm diameter top inspection hatch

- DIN 32-40 discharge system with butterfly valve

- Integrated spray ball

- CO2 carbonation system (3/8" inlet)

- Spiral mixing blades

- Adjustable wheels

The cylindrical section and conical bottom are equipped with thermal insulation, ensuring stable temperature throughout the processing cycle. Spiral mixing blades on the bottom and cylinder enable uniform mixing.

This industrial mixing tank is an ideal solution for beverage manufacturers requiring precise pressure and temperature control. The equipment is perfect for producing soft drinks, juice beverages, and other liquid products, ensuring high quality and efficient production process.

Keywords: isobaric mixing tank, beverage industry equipment, stainless steel mixer, industrial mixing tank, 1000L mixer, juice industry equipment, food mixing equipment, beverage mixing tank

| Weight (kg) | 0.000000 |

| High (m) | 0 |

| Width (m) | 0 |

| Length (m) | 0 |

.png)